With all of my benchwork now complete I’ve come to the real sticky part for me, deciding on a track plan. I’ve realised I am going to have to better identify what industries I plan to model on my layout, and how big they will be.

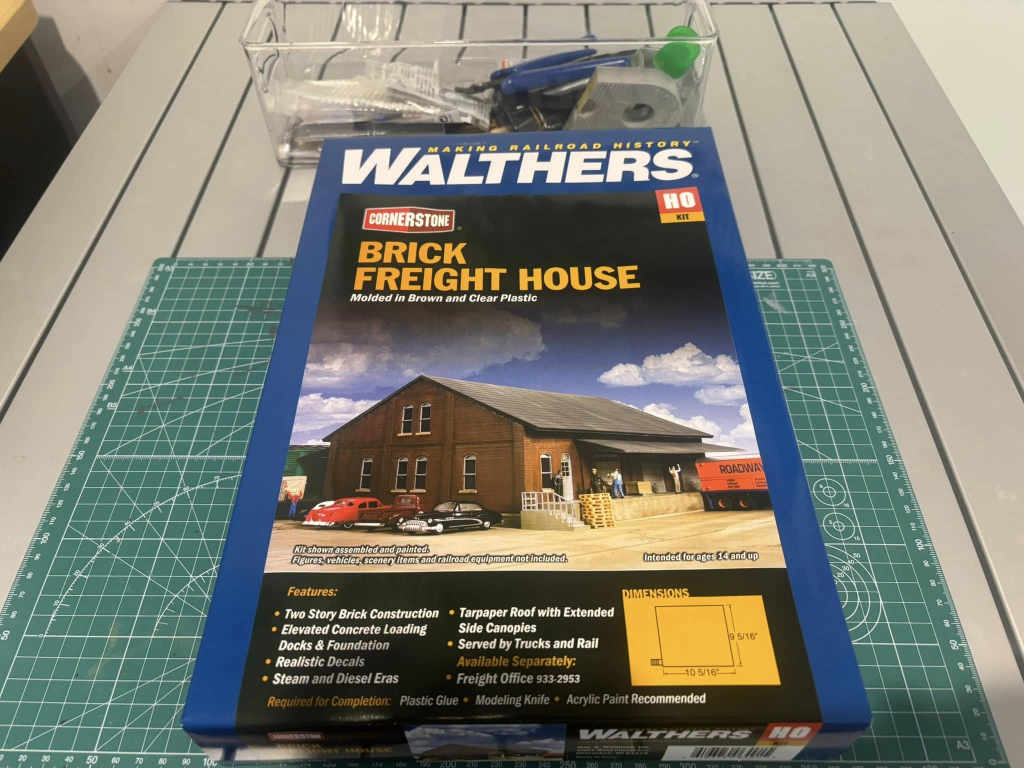

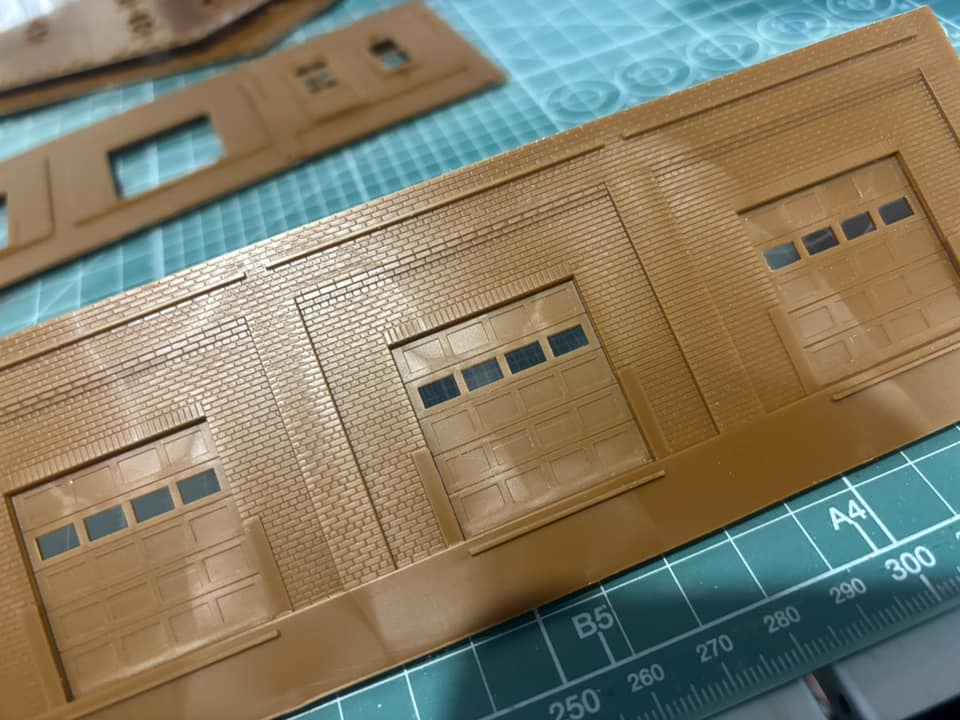

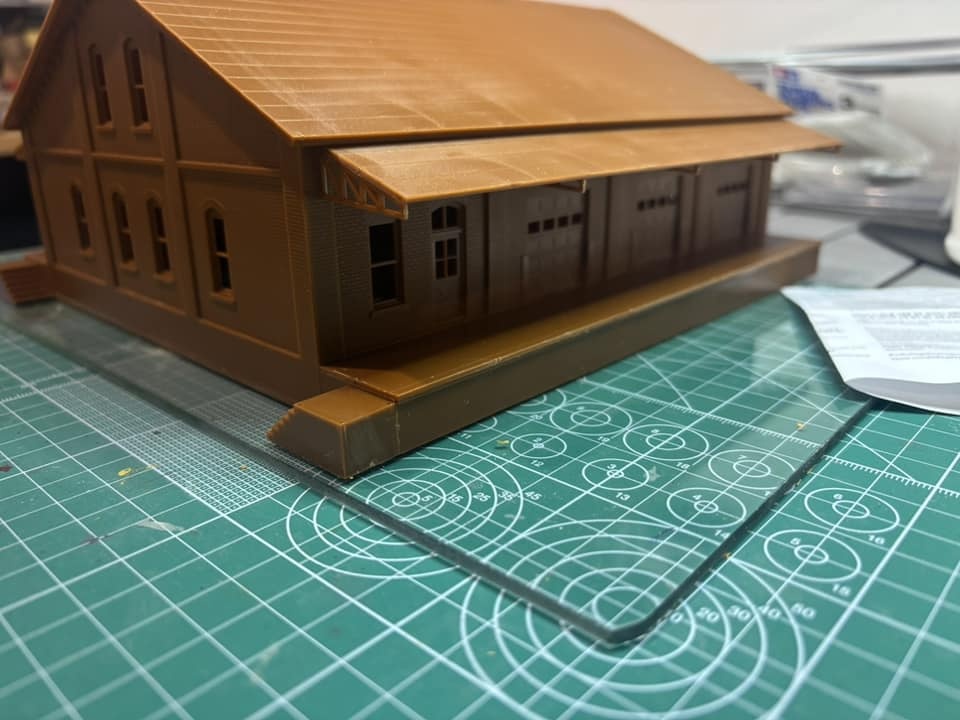

As lots of my rolling stock are going to be freight/contrainers, this kit jumped out at me when I was at the train store.

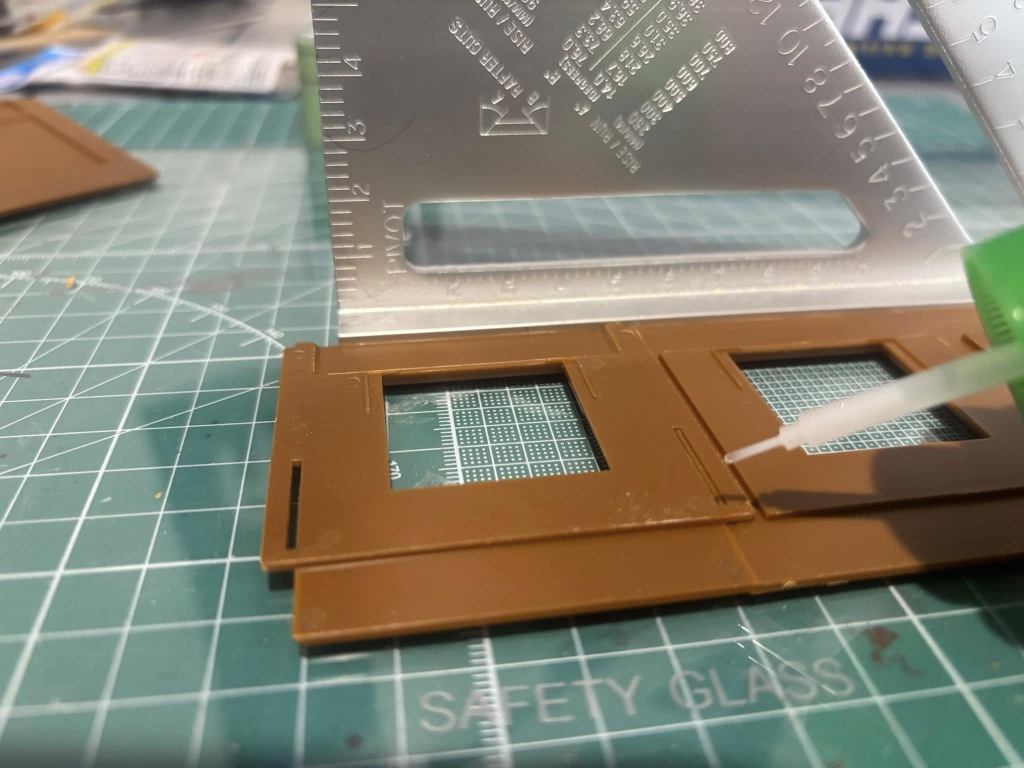

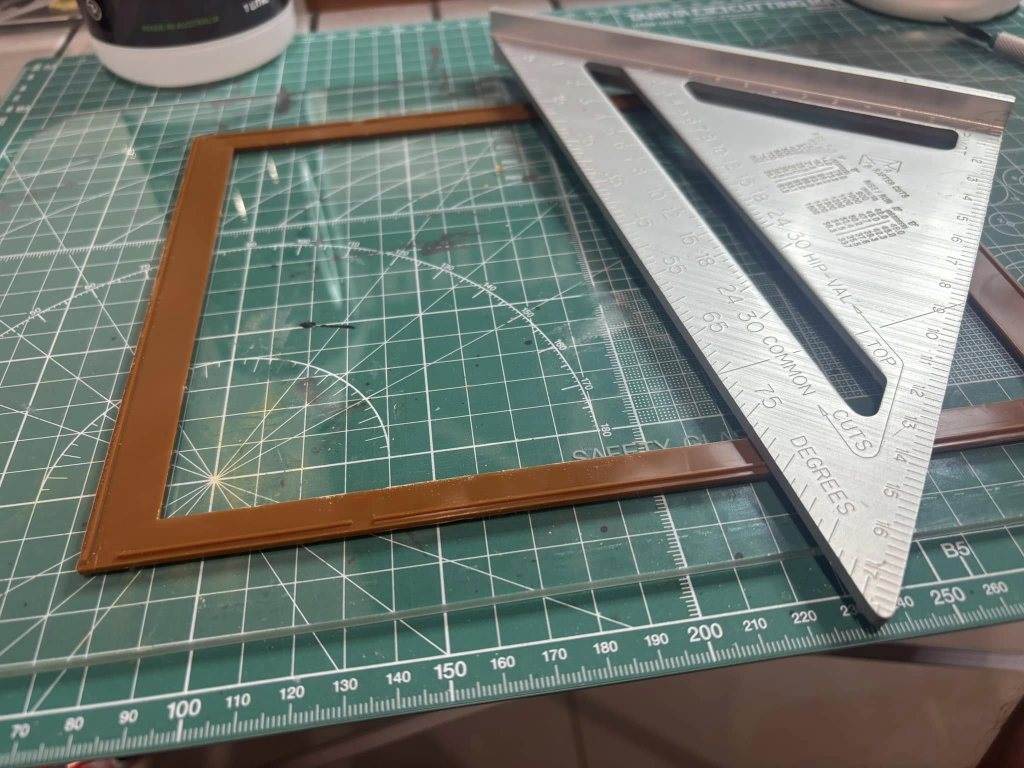

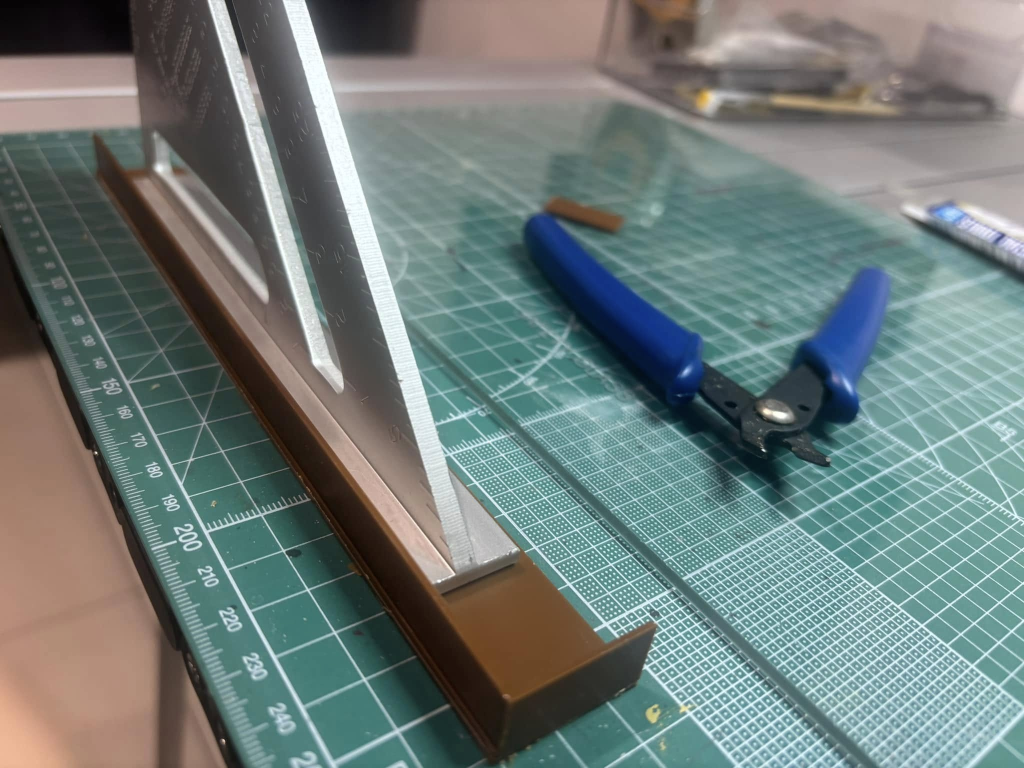

Not being much of a party animal, I strapped myself to the bench for NYE to make a start on it. My modelling table I use for now is not exactly super even and If I’m going to be building a structure thats square I need a better surface. I use this glass shelf from a fridge to model on and it it’s a great size to make sure everything lays down evenly.

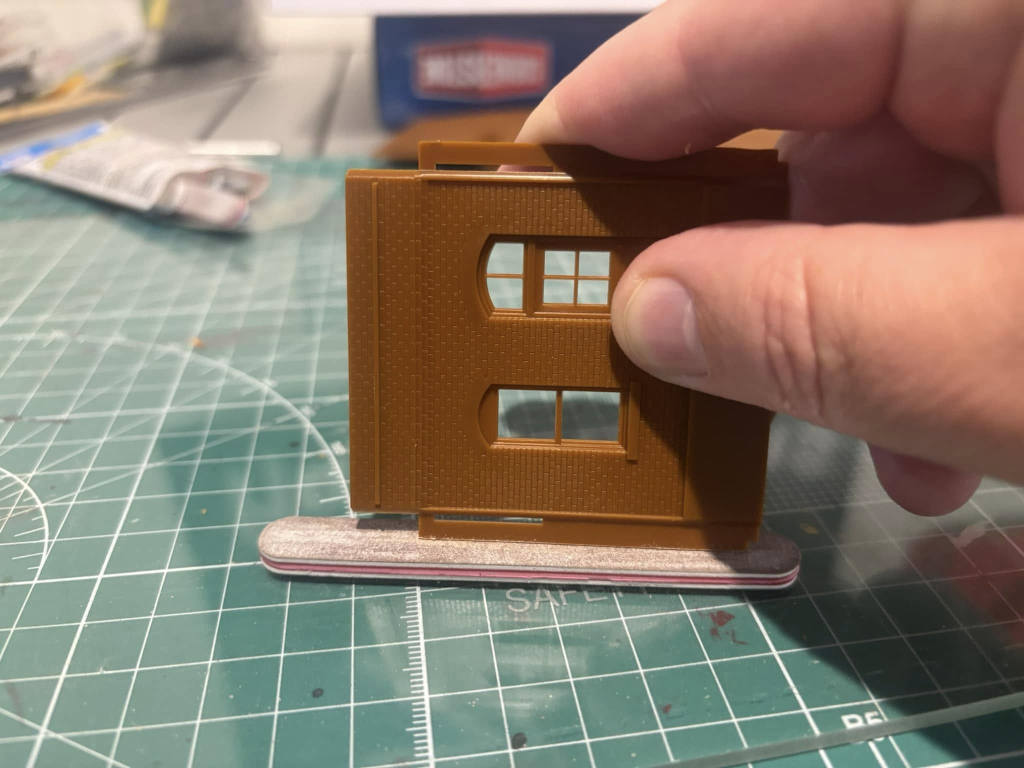

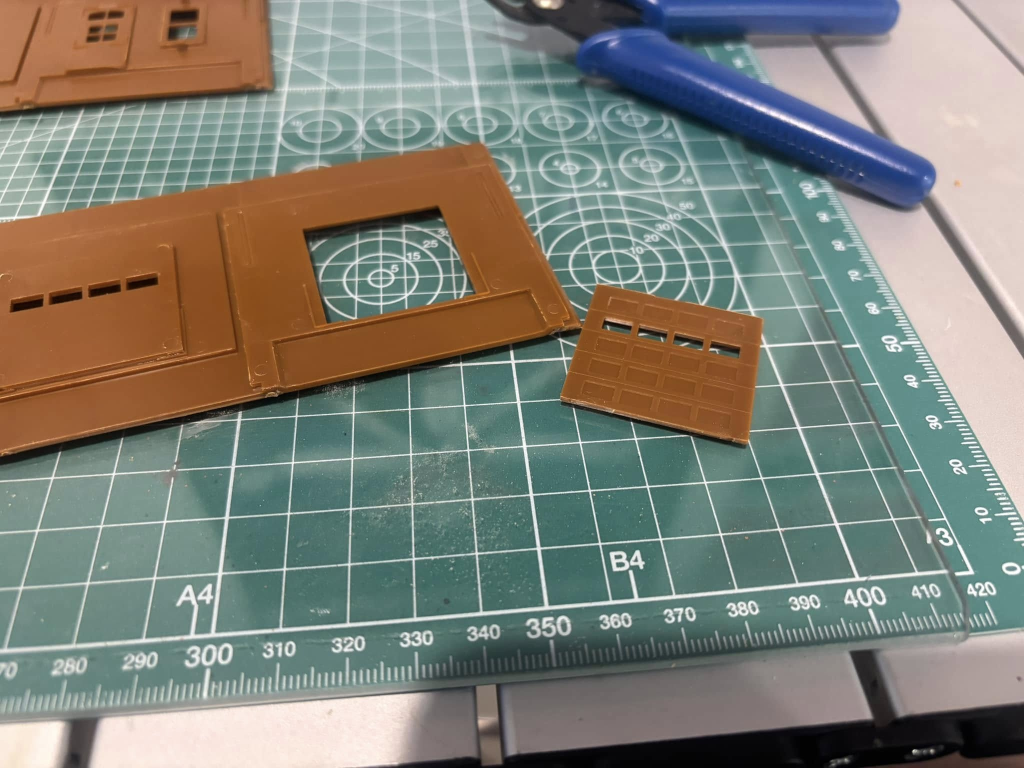

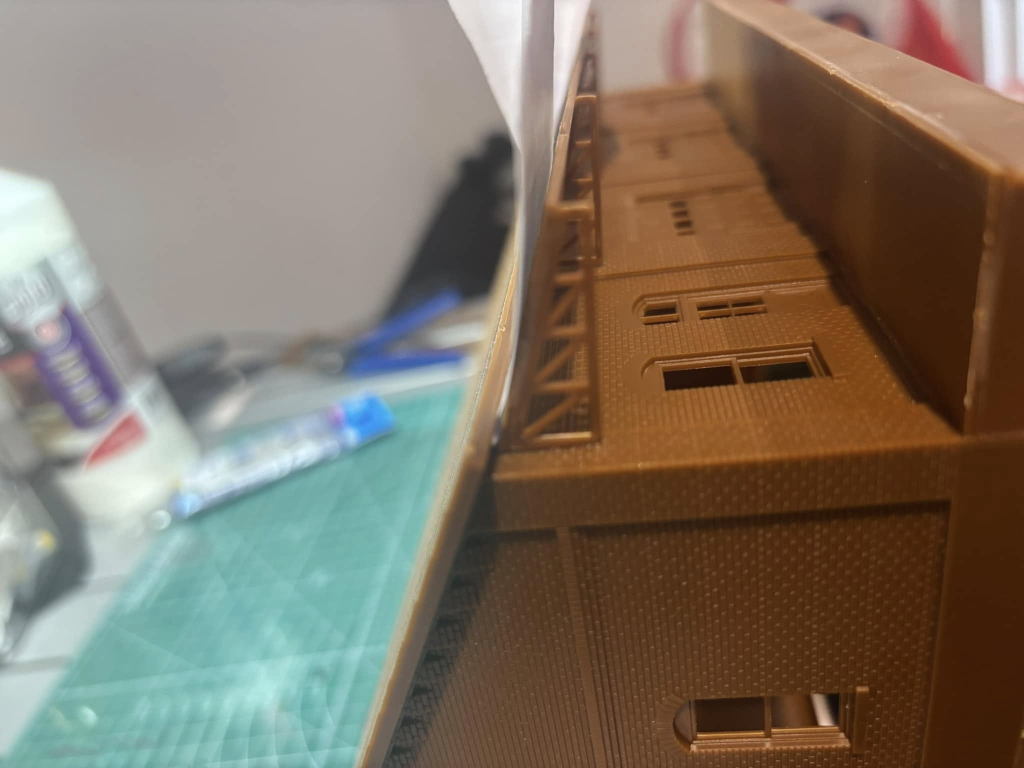

As usual, I clipped parts from the sprues as required and cleaned up where they were joined to the sprue with a hobby knife and sanding boards. All were glued with Tamiya Extra Thin Cement.

Every step I used a square to keep things aligned.

It was then time to glue the roller doors in.

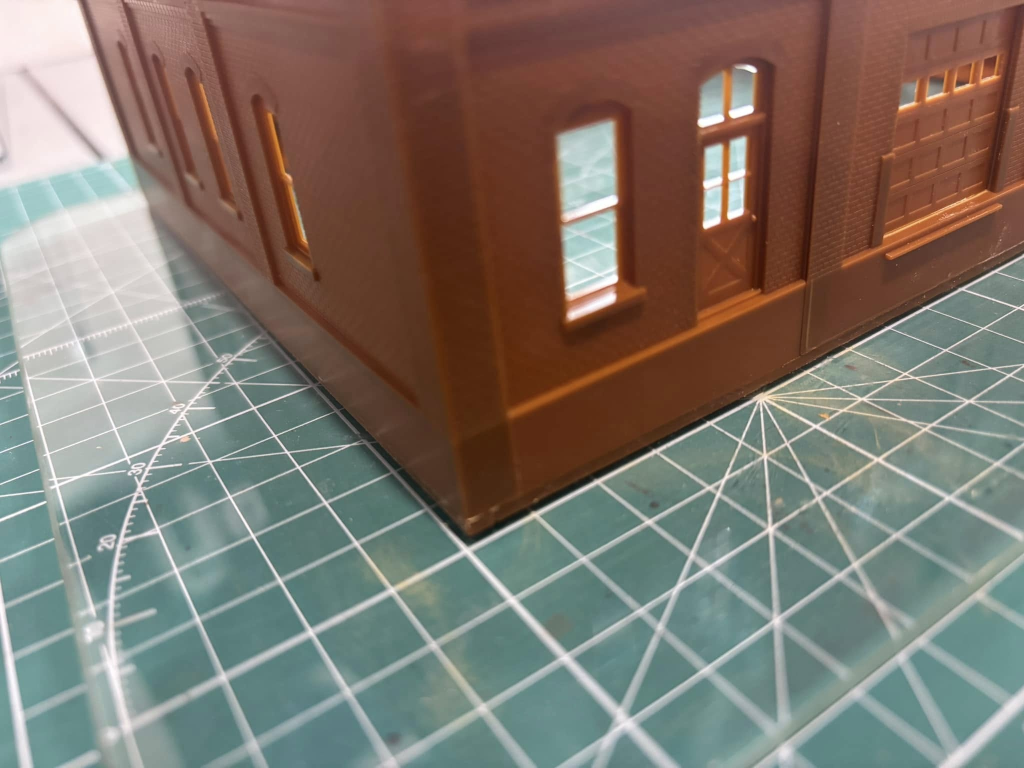

Once the doors were dry, it was time to start joining walls. I used a square to get good 90 degree corners and some heavy objects to keep them in situ. I really should invest in some of those speed blocks.

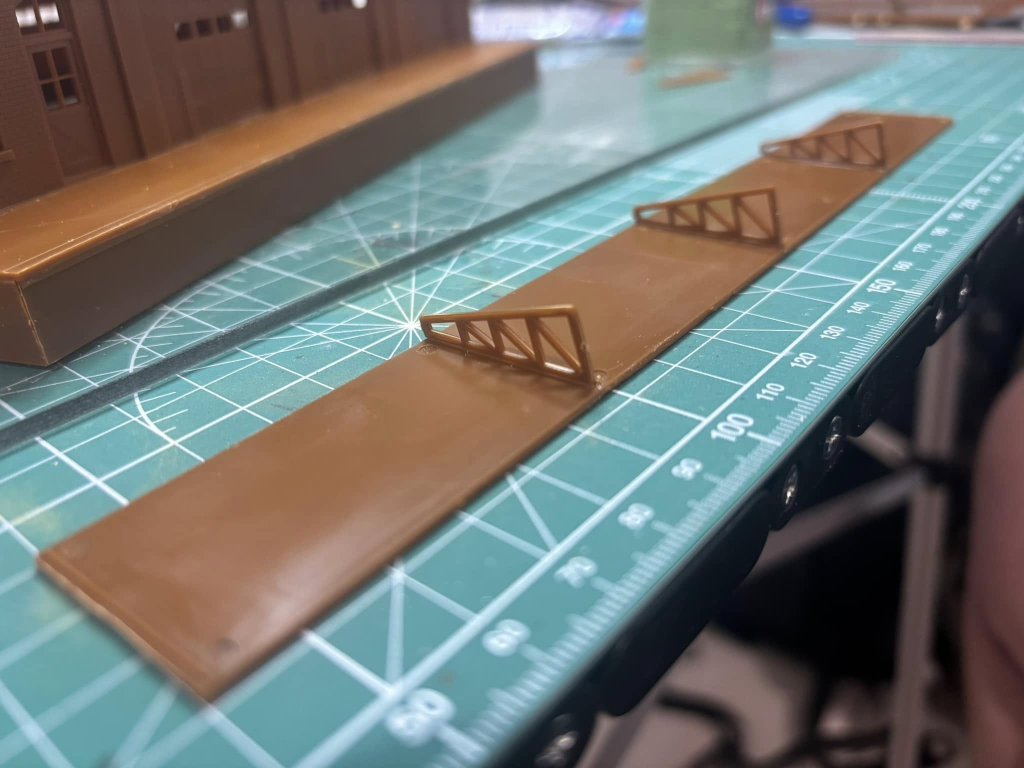

While the four walls were curing, I laid out and assmbled the sections for the base, then joined the two sub assemblies

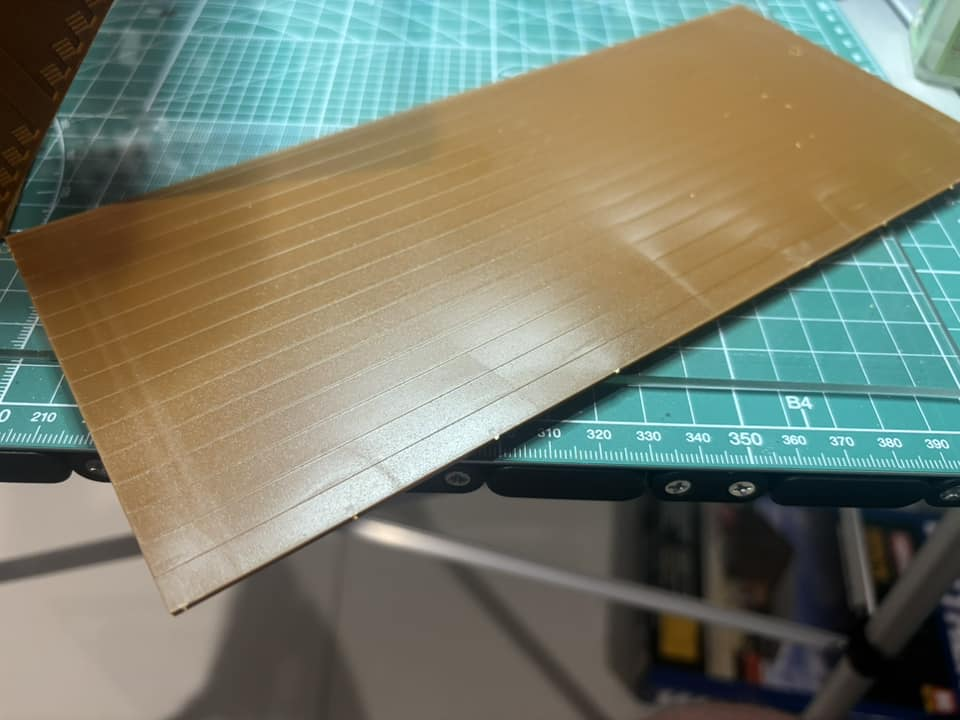

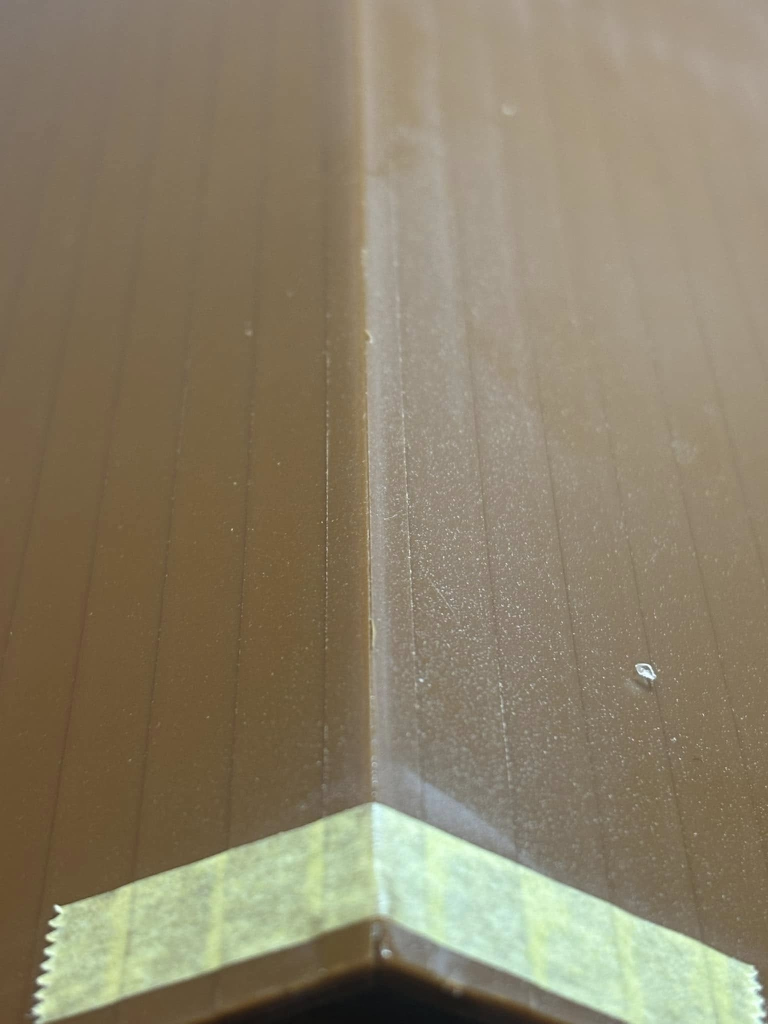

Next up were the roof panels. I used Tamiya Masking Tape to keep the join along the roofs apex nice and tight while the glue set. I’ve used Tamiyas tape a lot in scale modelling and I don’t think there is a better product. It’s masking ability for painting will surely be highlighted in further posts.

I’m sure readers would agree that the great part fitment and the tape made for a very nice join.

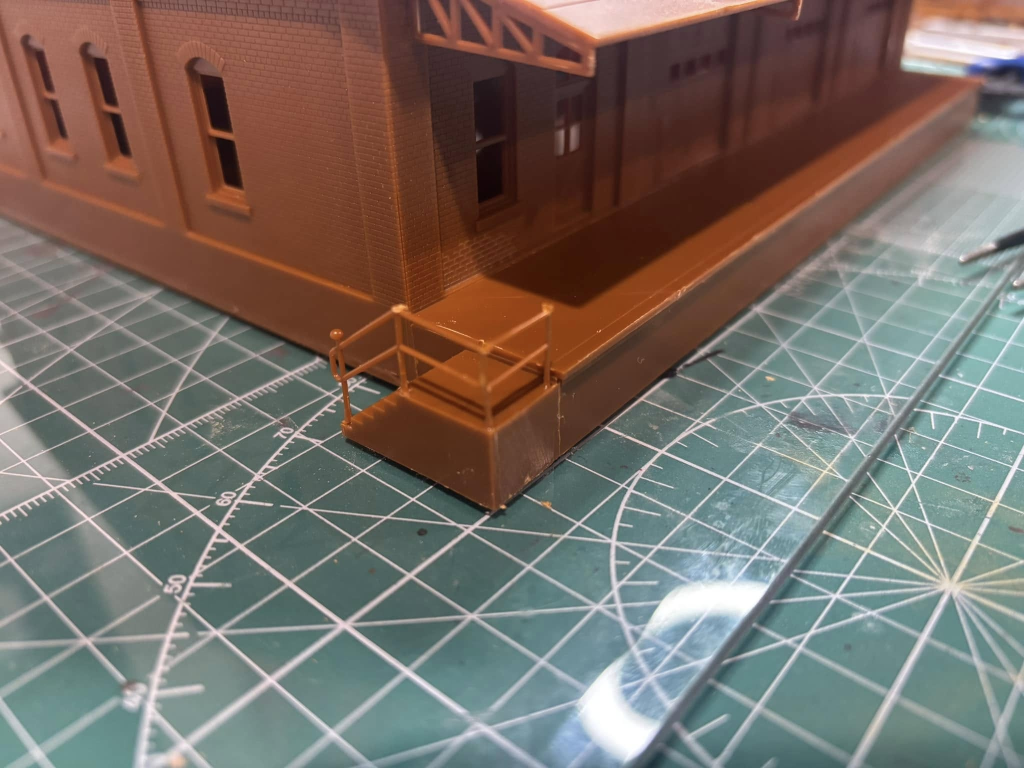

Next were the platforms, which are assembled seperately then attached to the building. I also affixed the stairs to them.

Next I tackled the awnings. I did have to use some folded paper to help wedge them in position while gluing. Sometime a small amount of tension can be achieved this way to keep a tight and even joint while the glue cures.

All that was left were the handrails. No matter how gentle I was, removing them from the sprue did cause some deformation and in one section, a breakage. This was with manual cutting of the parts, I think next time I might employ a disk on a dremel, or cut further away from the part first and then work my way in. Nevertheless, I got them glued in place and the warpage ont he part does make it look like they’ve suffered damage from a truck or forklift, so once painted may stay but if I’m not entirely happy I will replace and use wire or styrene rod.

So what’s next?

Prior to writing this blog post, I had filmed a video on this building and a layout update for youtube.

I posted the link to the video in my local NMRA Divisions Facebook group for feedback, and I got a comment from one of the members in response to me mentioning trying to find kits that would pass for having an Australian feel.

He mentioned that what he had done was use corrugated styrene sheet for the roof and I think it’s a brilliant idea. I’ve already glue the kits roof on but I think with the sheet on top with the end boards/guttering and barge cap it still should look ok so I plan to give it a shot. He did write about this on his own blog which you can read here https://nimmitabelextension.blogspot.com/. Thanks again for the idea Darren!

Once I’ve settled on a location and established the track plan I look forward to breaking out the paint and seeign this model come alive. Until next time 😉